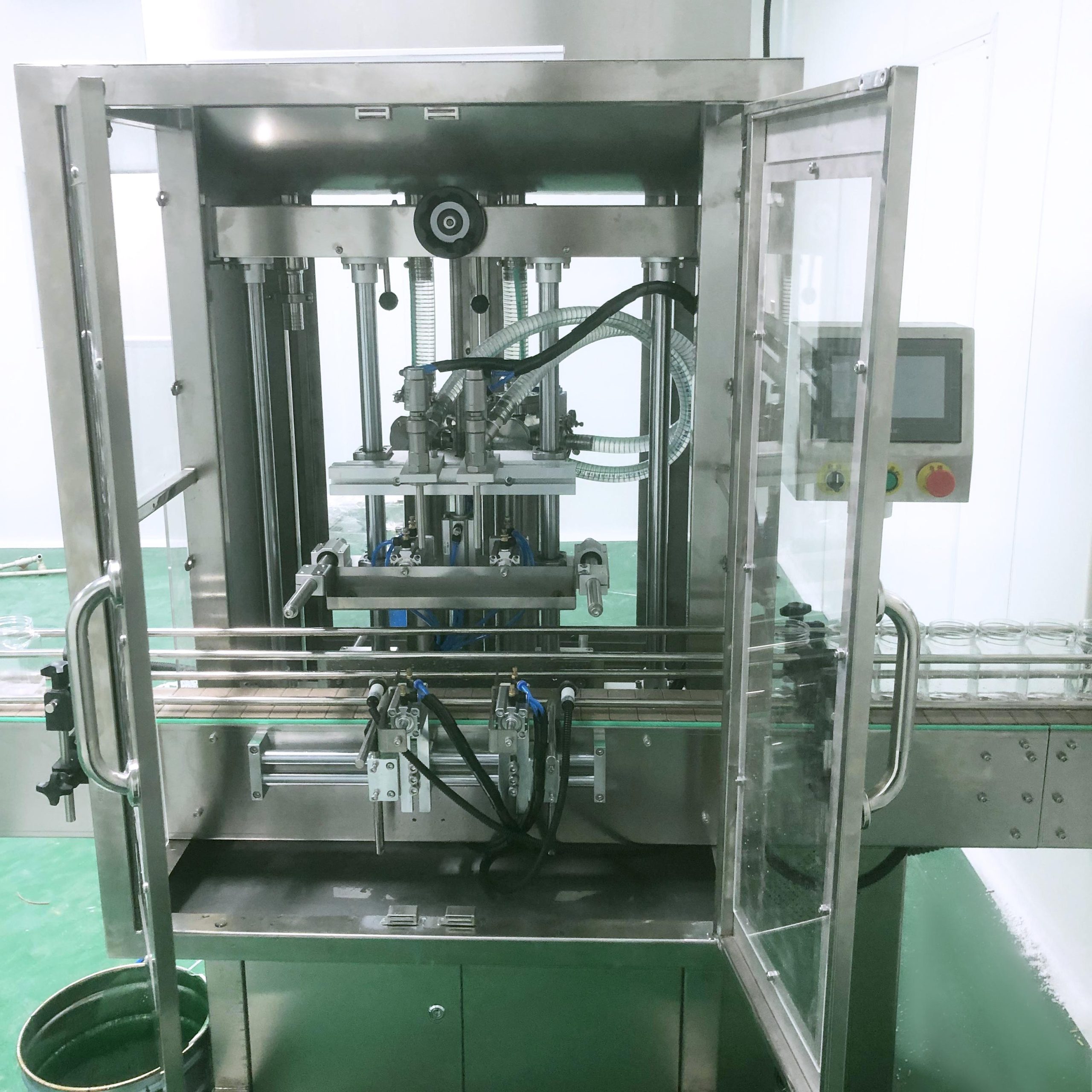

Suitable for honey processing plants to realize filling automation and complete bottling quickly, accurately and hygienically.

This automatic filling machine is specially developed for high-viscosity liquids and is an ideal filling solution for products such as honey, syrup, edible oil, shampoo and shower gel. Advanced control systems and precise filling efficiency reduce labor costs and improve production efficiency, thus bringing long-term benefits to your factory.

This product is customizable and offers a variety of options to meet different production needs.

This automatic filling machine is equipped with a variety of configuration options for different production capacities and bottle sizes, ensuring that it can be customized according to the specific needs of the enterprise.

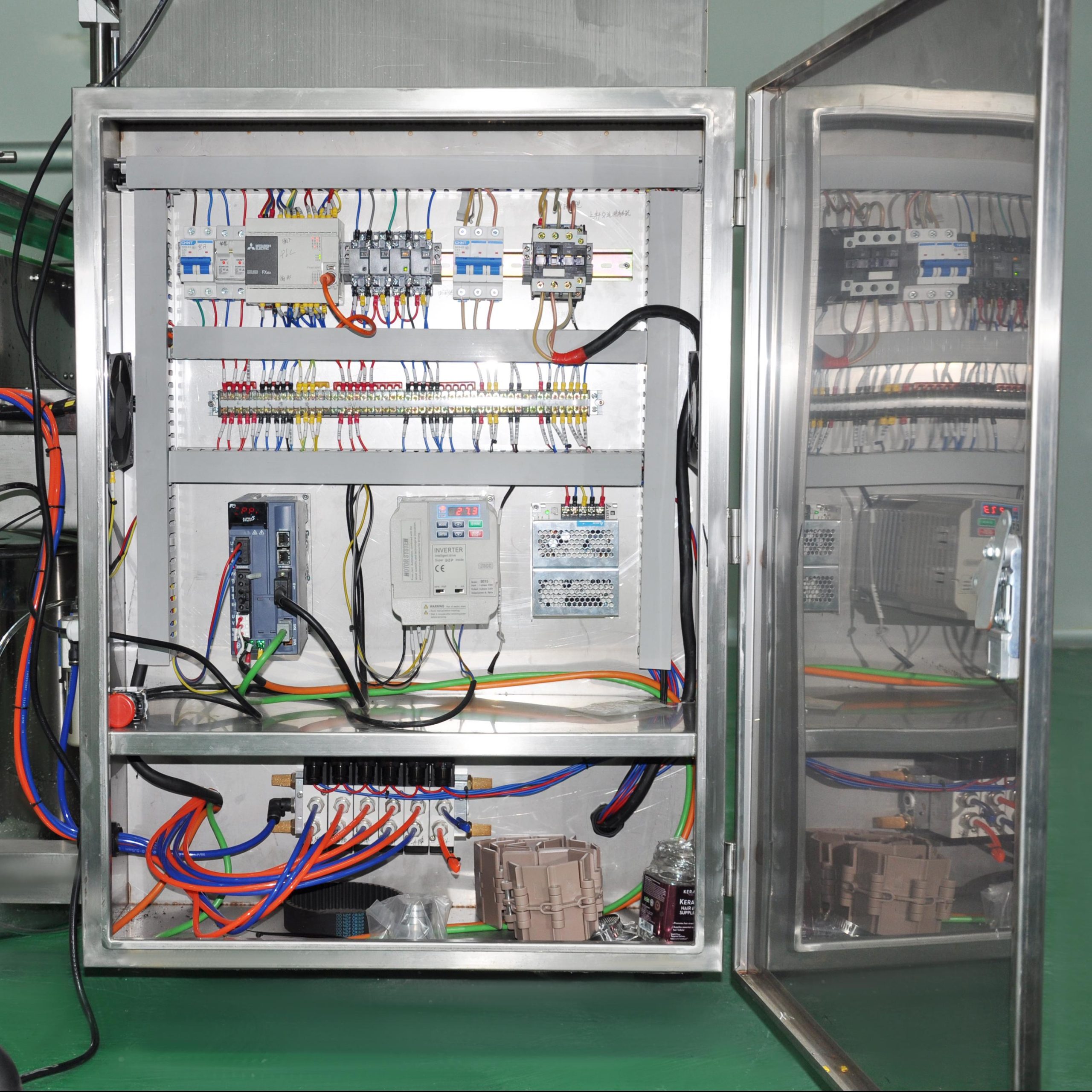

We will check each machine before shipping, and our machine’s warranty period is 2 years, if the broken parts can’t be repaired, we can send new parts to replace the broken parts for free, but you need to pay the express cost yourself. if over the warranty period, we will also help you solve the problems via negotiation, and we supply the technical support for the whole life of the equipment.

Not only, we can customize the machine according to your specifications, and use top brand name components.

It will be sent within 7-15 working days after receiving your advance payment.

Multi-sweet has very strong capability to produce high-quality bee products, and our long-term and reliable partnership with lots of logistic companies allows us to send goods to you fast at very favorable prices. If you have your own freight forwarding company, we are also willing to deliver the goods to them in promptly.

sample order after we receive your money.

large order after we receive your prepayment.

Tell Us

Your Needs

We'll provide the best honey machine solution and factory price for you.

Partner with a trusted honey machine manufacturer—start here.